Inatool

Inch .250 Flex Edge Finder

Inch .250 Flex Edge Finder

Couldn't load pickup availability

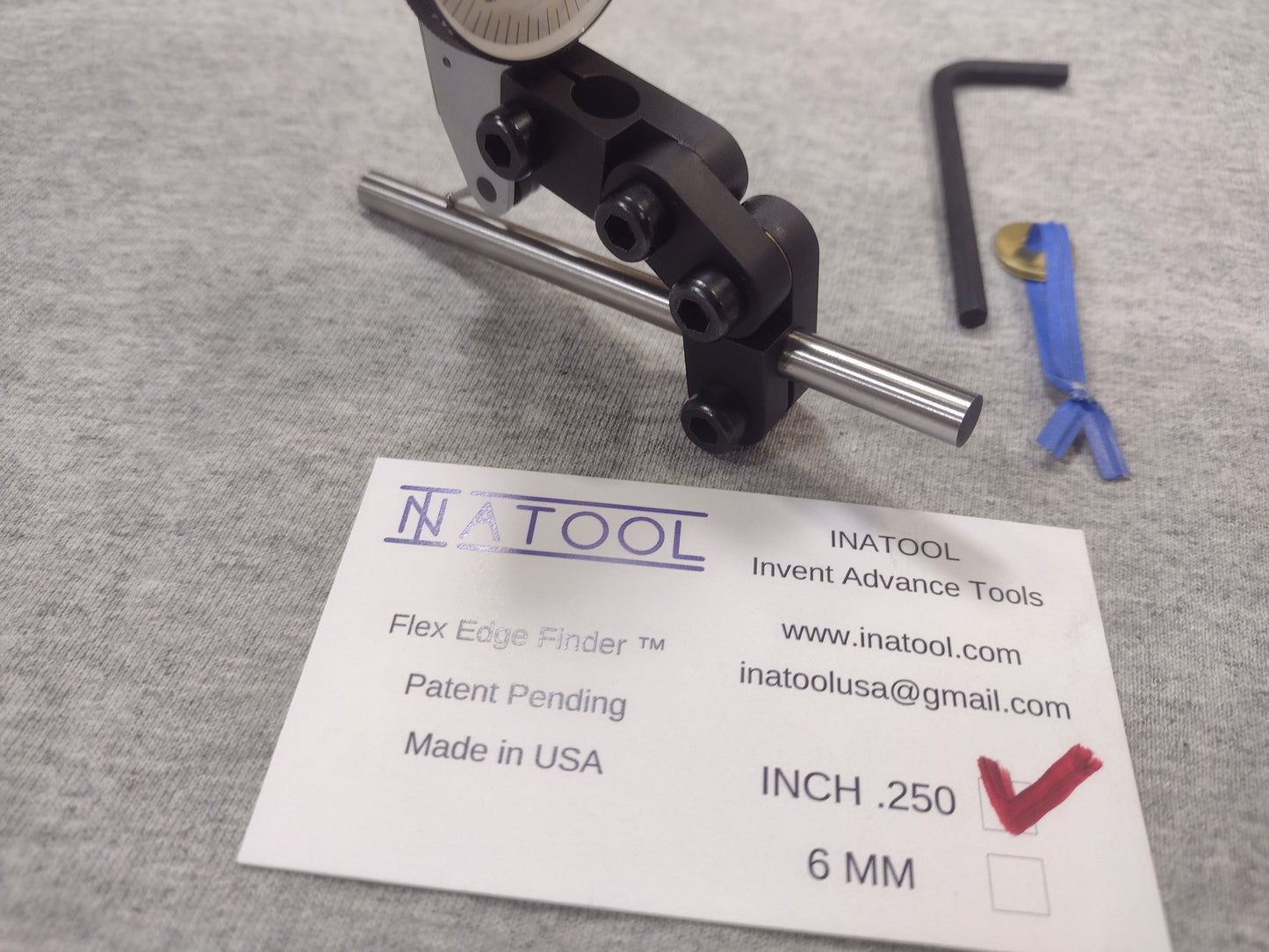

The Flex Edge Finder is a patent pending locating tool for use on machine tools. Flex Edge Finder makes edge finding fast, easy, and precise.

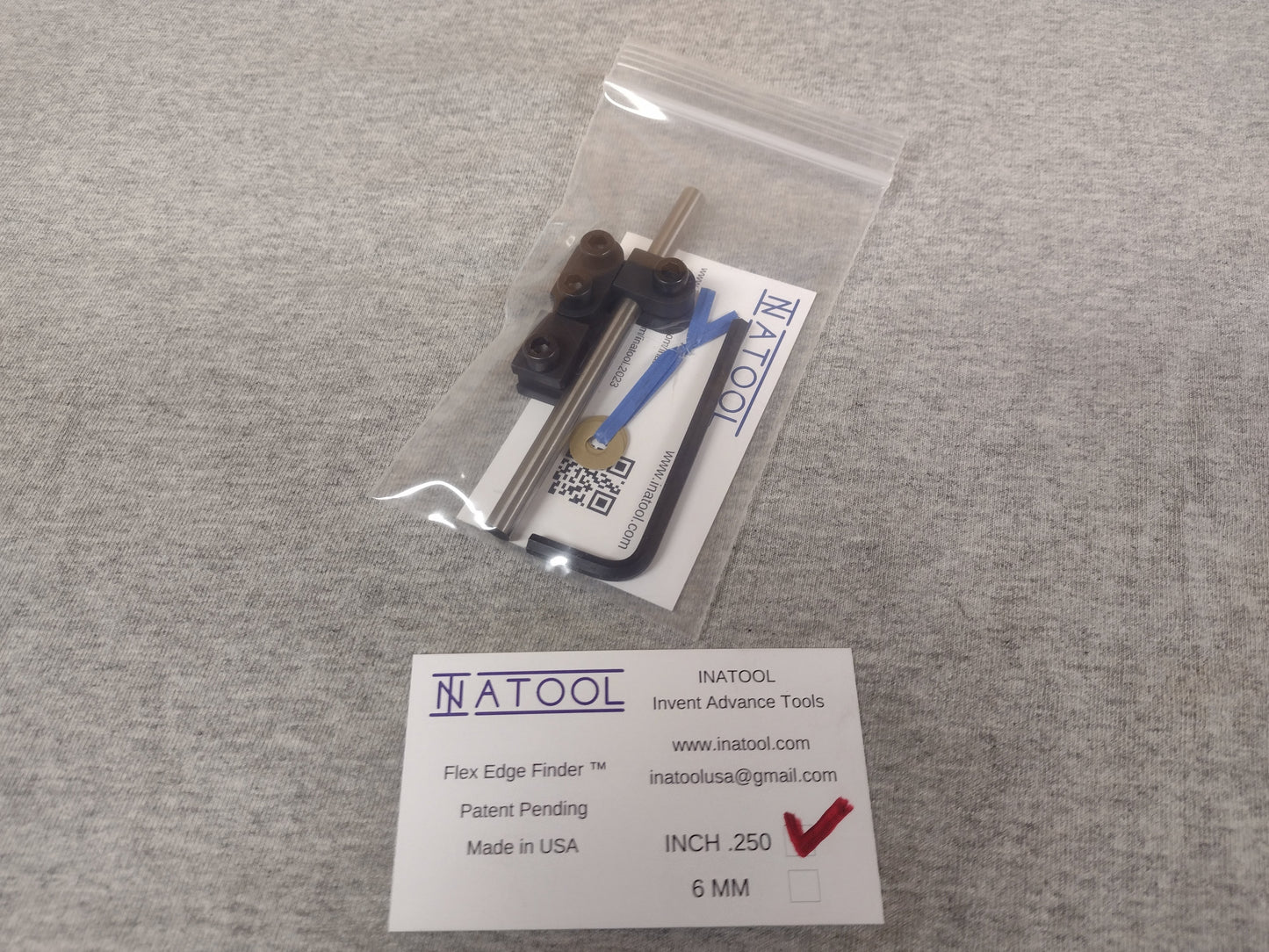

Included: flex shaft, mount assembly parts steel black oxide, screws, shims, hex wrench

Not Included: Dial Test Indicator measuring device

Flex Edge Finder uses a direct reading from an indicator, which ensures no overshooting or uncertainty of the edge location on workpieces.

Flex Edge Finder compatible with many brands of dial test indicators with dovetail mounting rails. Common dial test indicator brands: Interapid, Brown & Sharp, Fowler, Mitutoyo, Starrett, etc.….

Dial test indicators are usually already owned by machinist because of common use in machine shops for setup and inspection.

Make sure you choose your desired measurement system. Flex Edge Finder sold with inch .250 or 6mm flex shaft. You may work with both measurement systems and can convert the size of edge finder tip to inch or mm. Also, both sizes can be purchased for your convenience if you work with both measurement systems.

Be careful not to cross thread the screws on the Flex Edge Finder. If having trouble threading in screw rotate the screw counter clockwise until feeling the start of the thread and then rotate screw clockwise.

M5 screw torque - 15 inch pounds, 1.69 Nm

The included shims allow indicator tip to be set close to center of flex shaft. Indicators often do not have tips centered in the middle of dovetail mounting rails. Put shims in between joint 1 or joint 2 to move indicator left or right. Center tip roughly in the middle of the flex shaft by eye. It is not necessary to be exact.

If either the shaft clamp or dovetail clamp have not sprung open far enough because of over tightening. Simply take a piece of sheet metal (ruler) insert in slit, put the screw though the threaded side and open up the clamp slightly more. Remember to put the screw back through the clearance hole side or it will not clamp.

When you mount the indicator and set the tip against the flex shaft it is easiest to have the flex edge finder mounted in your mill spindle or a vise with soft jaws.

Getting the indicator in position on the Flex Edge Finder. First, tighten the flex shaft clamp in a desired position exposing roughly .875 inch or 22mm of flex shaft, which will be mounted in collet. Second, move the indicator close to a desired position and tighten up the screws on the mount assembly. Third, loosen the dovetail clamp and slide the indicator forward to contact the flex shaft and bring to where you want the indicator bezel to be zero. Fourth, tighten up the dovetail clamp to keep indicator in desired position. Finally, move the indicator bezel to zero. Check to make sure indicator has travel in both directions by flexing the flex shaft by hand.

If Flex Edge Finder has run out when mounted in a collet or drill chuck run out can be canceled with 180-degree rotation checking and splitting the difference on the indicator.

Use a light finger force to check and prevent over shooting the edge of workpieces.

Notice: Use safety glasses if user error occurs the flex shaft may snap. Do not turn on machine spindle with Flex Edge Finder mounted, put machine in neutral.